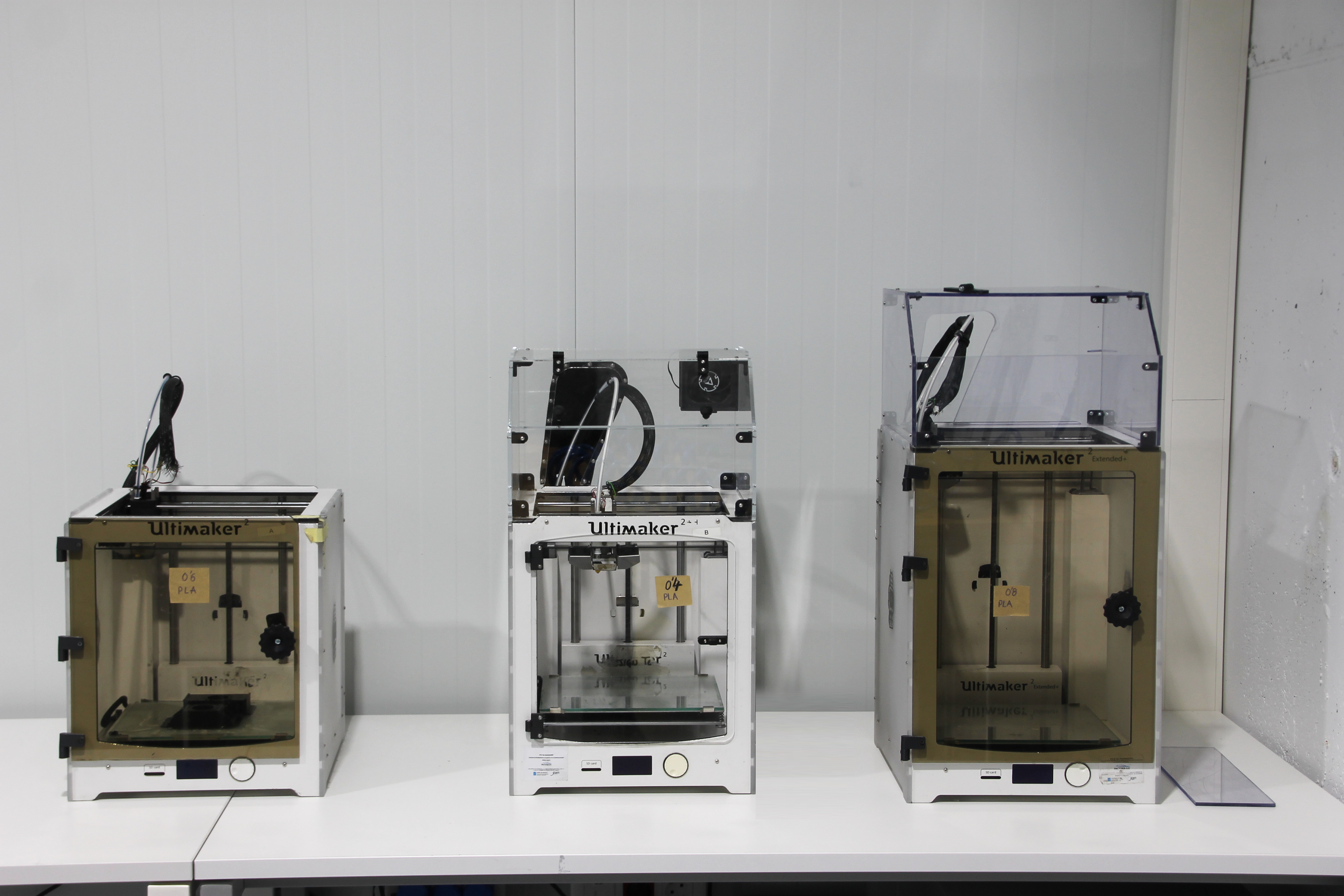

Our rapid prototyping lab allows us to bring ideas to life with speed and precision, thanks to an infrastructure equipped with state-of-the-art 3D printers utilizing FDM and SLA technologies. These technologies enable us to achieve final finishes and produce lighting components, adapting to the specific technical requirements of each prototype and delivering optimized solutions in terms of materials, durability, and level of detail. From functional parts to high-precision models, our manufacturing capabilities cover a wide range of product development needs, allowing us to produce fully functional prototypes.

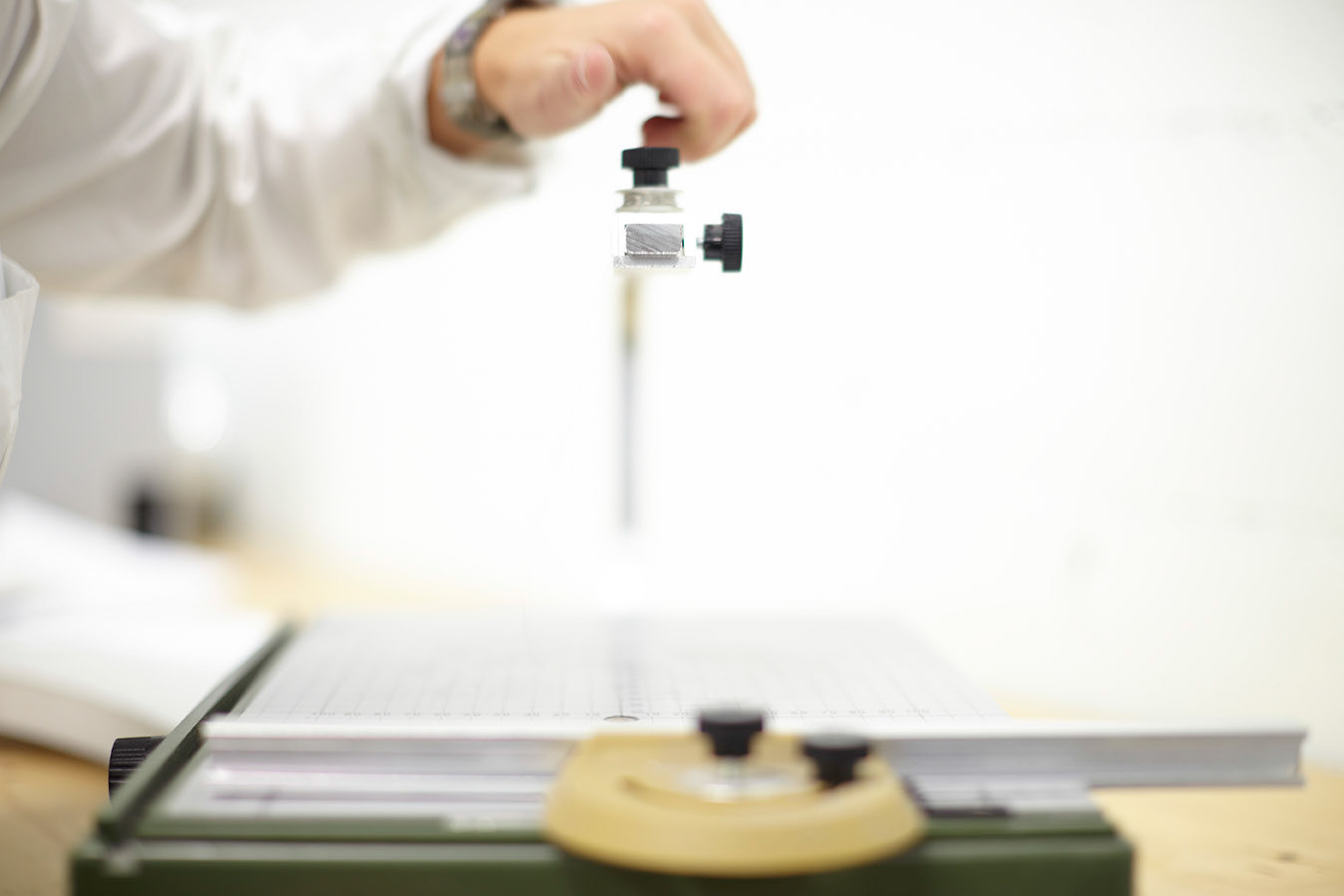

Additionally, we have a spacious, fully equipped workspace featuring specialized tools, assembly benches, finishing stations, and dedicated areas for testing and adjustments. This enables us to efficiently assemble prototypes and scale models, as well as conduct ergonomic tests, functional validations, and real-time design refinements. Our highly skilled team combines technical expertise, experience, and a meticulous approach, ensuring that each model is accurate, functional, and ready to move forward to the next stage of development.